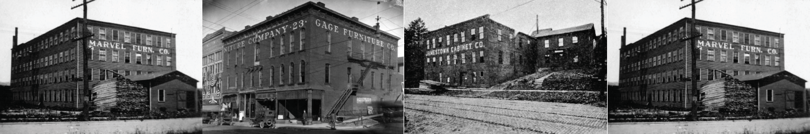

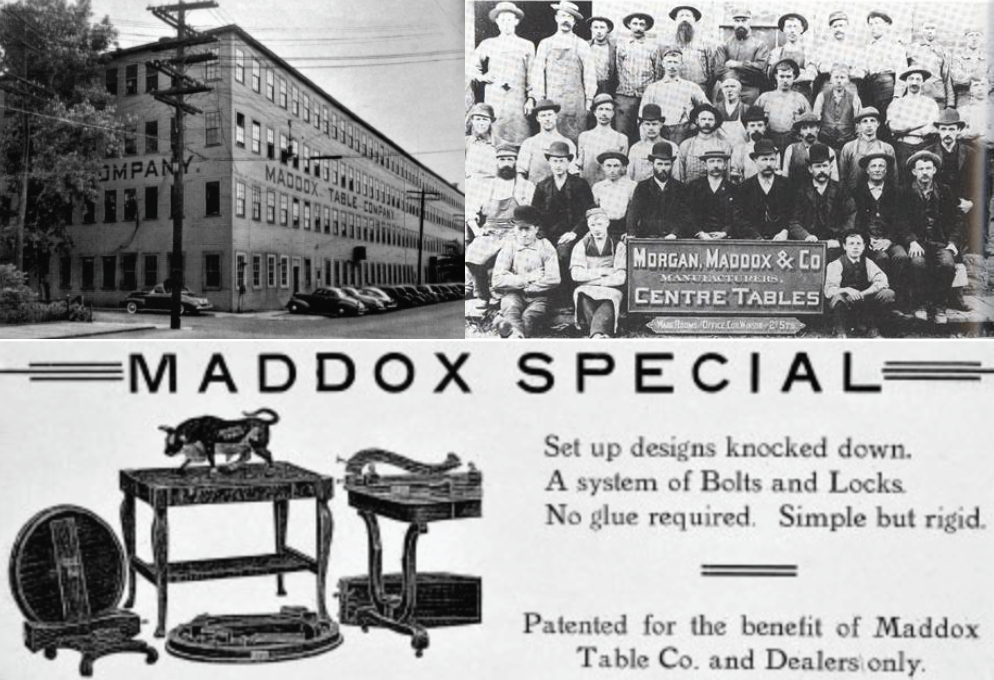

Jamestown is no stranger to the furniture business. In fact, one of the westernmost cities in New York was once dubbed the “Furniture Capital of the World,” as furniture manufacturing was its predominant industry.

Because of our hometown’s rich history in furniture production, our company pays homage to the community’s past as we continue to grow and carry on its legacy for years to come.

We Built this City On Timber & Water

Much of Jamestown’s success in the furniture manufacturing industry is rooted in the abundance of timber resources in its early days.

“In the early 19th Century, Western New York was heavily forested, with as much as 100,000 board feet of timber per acre in upland areas like Chautauqua County. Southwestern New York was rich in white pine, hemlock and such valuable northern hardwoods as maple, oak, beech, birch, chestnut, walnut, sycamore and cherry. Southern Chautauqua County was covered with dense pine forests.” (Paul A. Spengler, The Furniture Industry)

Jamestown’s proximity to major bodies of water, such as Chautauqua Lake and the Great Lakes, as well as heavily used waterways, such as Chadakoin River of the Erie Canal, also strengthened its position as a hub for the burgeoning furniture industry. Accessibility to these waterways in the early 1800s allowed easy transportation of wood products to places such as Pittsburgh.

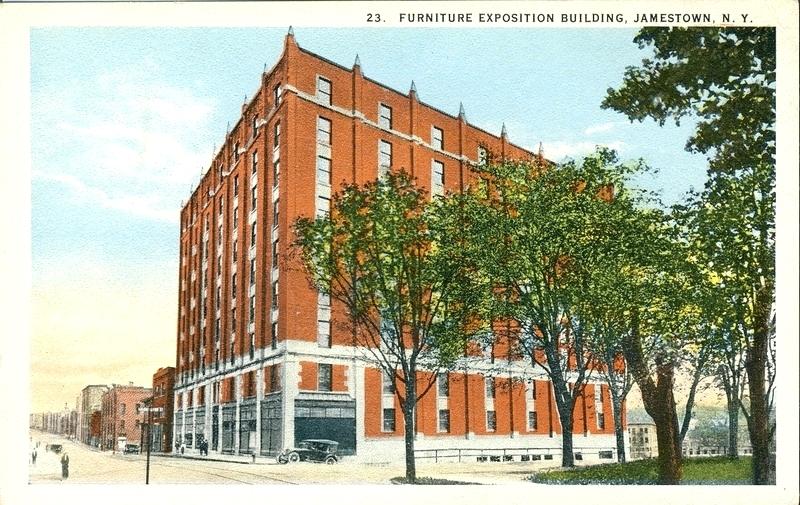

By the 20th century, the local furniture manufacturing had boomed so much that Jamestown became an industry destination. To meet the interest in Jamestown-produced furniture, the Furniture Mart Building was constructed to showcase good and hold expositions. The building still stands today.

Challenges & Continued Growth

The rapid expansion of the Jamestown area’s furniture manufacturing industry during its first century did provide its challenges to companies.

Of note, overharvesting of area forests through the 1850s required manufacturers to begin sourcing wood and other materials from outside the U.S.

Wars in the 1800s and 1900s also impacted production at area factories, as many of their workers were called to serve.

Near the end of World War II, Jamestown’s furniture industry got a bit of unexpected -- yet well-deserved -- publicity.

Furniture World, an industry magazine, published a special article, “Furniture Industry’s Part in World War II,” in its April 1945 issue. The article had a special message from Cliffton E. Mack, the director of Government Procurement. Mack thanked the manufacturers of the furniture industry for their “100% plus” cooperation.

While Mack’s sentiments were appreciated, there was no denying the war’s impacts and hardships faced by furniture companies in Jamestown and across the country.

“‘Furniture factories had lost many of their skilled craftsmen. Jamestown has 55% fewer men in (its) furniture plants than they had at the time of Pearl Harbor” Crawford wrote. “Only 11% of the Pearl Harbor employment is 45 years or younger. Men up to 82 years old are counted in today’s figures. Many of the younger group are disabled or returned veterans,’ Clyne Crawford, president of Crawford Furniture, Jamestown.” (Russell Bienenstock, Furniture World).

Wartime market conditions compounded matters for the industry, as costs for raw materials increased. Just like a century earlier, manufactures imported wood and materials to sustain operations at their factories -- often in limited quantities.

Despite the myriad challenges more than 200 years can bring, furniture manufacturing in the area evolved, prospered, and grew through the present day.

Furniture Manufacturing: Today, Tomorrow and Beyond

Though Jamestown’s furniture manufacturing industry today is drastically different from the shops of centuries ago where products were made by hand, it remains one of the area’s stalwarts. It’s poised to remain that way long into the future.

Jamestown area furniture manufacturers are part of nearly 200 other manufacturing facilities located within Chautauqua County, which employ approximately 10,000 and make nearly $5.1 billion in annual manufacturing shipments.

Before you make a decision on a casegoods manufacturer, consider choosing a manufacturer with not only experience in the industry, but also the history to back them up.